Smart European Space Access through Modern Exploitation of data science

Project funded by European Union

This project has received funding from the European Union’s Horizon 2020 research and innovation framework programme under grant agreement No 821875. Click here for more info

3years

8partners

4countries

3millions budget

The project

Demonstrate the ability of european space companies to work together and to reduce the costs using data science for predictive quality, predictive maintenance and supply chain agility.

objectives

DIRECT OBJECTIVES

Develop a complete data management framework to proactively manage risks in new automated production and operations.

Develop new predictive maintenance and quality components to implement new automated launcher production and operations maintaining quality and reliability. The global project technical progress objective is to pass from TRL 3 to TRL 7.

Implement new logistic processes (adaptative operations) that allow an optimal management of resources in an environment where resources are shared among different organizations and products.

Accompany the consequent new logistic processes (adaptative operations) that allows an optimal management of resources in an environment where resources are shared among different organizations and products.

Evaluate other possible sectors (for which the proposed predictive framework could be applied to create a large ecosystem with tools for predictive maintenance and quality.

INDIRECT OBJECTIVES

Increase flexibility of the production of Ariane 6 and future programs manufacturing facilities (in France and Germany).

Create an ecosystem involving the overall European launcher industry and possibly other sectors to share knowledge and implement new more effective industrial processes with less risks and costs.

Improve competitiveness of European launch service from the Guiana Space Center (CSG) spaceport by improving service availability and reducing overhead cost.

(Deliverables, Roadmap, Achievement, …)

usecases

Friction Stir Welding predictive quality & maintenance

ArianeGroup uses FSW or Friction Stir Welding technology – a solid-state welding process – to join Ariane 6 parts together. This is a key process within the Ariane 6 tanks assembly operations, that has to be mastered both in terms of quality, time and cost. So how can ArianeGroup reduce the time it takes to weld a tank by also improving its quality ?

Within the framework of the SESAME project, multiple sensors have been placed on the FSW. Those sensors collect a large amounts of data coming from its Computer Numerical Control while in operation. Every 100 millisecond 1500 variables such as temperature, speed, or position are gathered. They are then sorted and analyzed by Data Scientists (helped by algorithms) to formulate a “health status” both of the tank being welded and the FSW machinery. This way, operators can be made aware of a non-quality or malfunction and intervene before it even occurs, guaranteeing improved quality and safety at lowered costs.

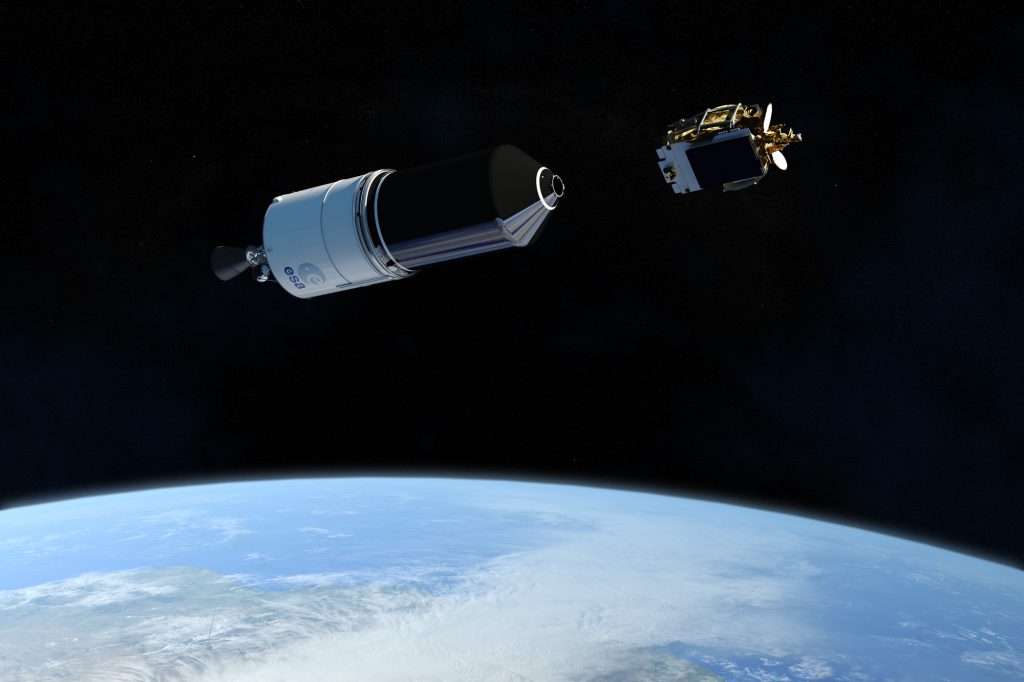

Guiana Space Center optimization of resources usage

Since several decades, the Guiana Space Center has seen hundreds of launch campaigns. This vast area also hosts a tremendous amount of multiple space activities that share the same resources (i. g. tools or on-site transportation). As a consequence, employees don’t always immediately have access to the resources they need to perform a specific task. So how can ArianeGroup maximize its resources potential and increase its supply chain agility ?

Within the framework of the SESAME project, trackers are deployed to be placed on the different resources and collect geolocation data. They are then crossed with other data, such as scheduling or resources needs for a specific task or project, before being processed and analyzed by algorithms. As a result resources availability and utilization is maximized while the schedules are easier to manage.

News

T-minus digital Data automation in the European space launch industry

SESAME, or ‘Smart European Space Access through Modern Exploitation of data science’, was a three-year research project, funded by the EU and conducted by 8 partner organisations.

It aimed to demonstrate European space companies working together and reducing costs by using data science for predictive quality, predictive maintenance, and operational planning optimisation.

As the project draws to a close, we unwrap each partner’s discoveries, the project’s impacts – and identify future opportunities.

Link to paper : here

Publié le : 24 février 2023

Energy-Aware Model Predictive Control of Assembly Lines.

This paper presents a model predictive approach to the energy-aware control of tasks’ execution in an assembly line. The proposed algorithm takes into account both the need for optimizing the assembly line operations (in terms of the minimization of the total cycle time) and that of optimizing the energy consumption deriving from the operations, by exploiting the flexibility added by the presence of a local source of renewable energy (a common scenario of industries that are often equipped, e.g., with photovoltaic plants) and, possibly, also exploiting an energy storage plant. The energy-related objectives we take into account refer to the minimization of the energy bill and the minimization of the peaks in the power injected and absorbed from the grid (which is desirable also from the perspective of the network operator). We propose a mixed-integer linear formulation of the optimization problem, through the use of H-infinite norms, instead of the quadratic ones. Simulation results show the effectiveness of the proposed algorithm in finding a trade-off that allows keeping at a minimum the cycle time, while saving on the energy bill and reducing peak powers.

Link to preprint: here

Liberati, Francesco, Chiara Maria Francesca Cirino, and Andrea Tortorelli. Actuators 2022, 11(6), 172

Publié le : 28 juin 2022

Communication trophies

This year, ArianeGroup has participated to the Communication Trophies event, on behalf of the SESAME project. We are honored and humbled to be receiving the #1 award for the best website for companies with more than 250 employees.

Since 2 years now, the whole SESAME consortium has worked hard, alongside the BTG Communication agency, to bring the best communication package we could, and meet the European Commission expectations.

Year after year, we challenged ourselves to get better and better. And today, our work has been recognized. Today, we’re thrilled to share this recognition with you all, and want to thank all of our consortium partners who committed to this result.

We’d be pleased to welcome you on our website : http://sesame-space.eu/

Publié le : 6 décembre 2021

Operations Management of Satellite Launch Centers

Driven by the business potentials of the satellite industry, the last years witnessed a massive increase of attention in the space industry. This sector has been always considered critical by national entities and international organizations worldwide due to economic, cultural, scientific, military and civil implications. The need of cutting down satellite launch costs has become even more impellent due to the competition generated by the entrance in the sector of new players, including commercial organizations. Indeed, the high demand of satellite services requires affordable and flexible launch. In this context, a fundamental aspect is represented by the optimization of launch centers’ logistics. The aim of this paper is to investigate and review the benefits and potential impact that consolidated operations research and management strategies, coupled with emerging paradigms in machine learning and control can have in the satellite industry, surveying techniques which could be adopted in advanced operations management of satellite launch centers

Link to preprint: here

Tortorelli, Andrea, Alessandro Giuseppi, Federico Lisi, Emanuele De Santis, and Francesco Liberati. « Operations Management of Satellite Launch Centers. In « Ka and Broadband Communications (Ka conference) », Sorrento (Italy), September 30 – October 2, 2019 (Session IX, Part 2)

Publié le : 25 novembre 2021

Optimal Control of Industrial Assembly Lines

This paper discusses the problem of assembly line control and introduces an optimal control formulation that can be used to improve the performance of the assembly line, in terms of cycle time minimization, resources’ utilization, etc. A deterministic formulation of the problem is introduced, based on mixed-integer linear programming. A simple numerical simulation provides a first proof of the proposed concept.

Link to publisher : here

Link to preprint : here

Liberati, Francesco, Andrea Tortorelli, Cesar Mazquiaran, Muhammad Imran, and Martina Panfili. « Optimal Control of Industrial Assembly Lines. » In 2020 7th International Conference on Control, Decision and Information Technologies (CoDIT), vol. 1, pp. 721-726. IEEE, 2020.

Publié le : 25 novembre 2021

Data-Driven Analysis of Friction Stir Welding for Aerospace Applications

Industry 4.0 and the digitalization of the manufacturing processes have brought new opportunities and strategies for process control and optimization. Friction Stir Welding is becoming a relevant manufacturing technology for several applications, among them the aerospace sector. This work presents the first data analysis and characterization of the Friction Stir Welding process of the Pre-Final Assembly Line of the new Ariane 6 launcher.

Process monitoring data is captured and analyzed to provide predictive quality solutions for improving manufacturing key performance indicators and bring smart manufacturing and Industry 4.0 digitalization into the aerospace manufacturing sector. The results show promising performance for abnormal behavior detection, leveraging on a tailored data manipulation approach for this unique use case.

Publié le : 27 octobre 2021

SESAME : An Open Data Platform in the cloud era

Inaugurated last January, the SESAME Open Data Platform represents a major innovationor ArianeGroup and heralds a promising future of collaboration within the European spaceindustry.

How did this project come about ? What steps did it require ?

Let’s take a closerlook at a small revolution that is poised for great things.

A drive to share

For the past several years, ArianeGroup has been committed to digital transformation. The SESAME project, however, signals the willingness of European space companies to create new collaborative ways of working and to reduce costs, in particular through data science.

Publié le : 31 mars 2021

ArianeGroup, SESAME project special guest at a one-day COMET event

How – and why – does the SESAME project integrate the human factor into its development process? This is the subject that Fabrice Blondeau, SESAME programme manager at ArianeGroup, tackled during a workshop organised by the CNES-supported COMET network.

COMET, a community of experts

Since its launch in 1998 by CNES, the COMET group of expert communities has regularly brought aerospace specialists together to share their knowledge, feedback and expertise, for everyone’s mutual benefit and to prepare for the future. With a focus on new technologies and processes, these encounters help to advance professions and improve working practices. They are also an opportunity to promote exchange and cooperation between the space sector and other sectors of activity.

Today, COMET comprises 20 communities totalling more than 3,000 experts from the academic, industrial and institutional fields. Around 60 days of exchange forums of many kinds are organised every year – think tanks, workshops, colloquiums, visits, good practice guides, discussion with experts, etc.

Publié le : 9 novembre 2020

Everything you want to know about SESAME.

Co-financed by the European Commission and under the leadership of ArianeGroup, SESAME officially started on the Les Mureaux site. By combining European cooperation and Data Science, its goal is to improve Ariane 6 competitiveness.

In more concrete terms, Smart European Space Access thru Modern Exploitation of Data Science is a project which aims to improve manufacturing and supply chain operations of European launchers thanks to digital technologies. This consortium combining ArianeGroup, CNES, Capgemini, Predict (France), Eurecat (Spain), Vitrociset, Crat (Italy) and SNSPA (Romania) will work for the next 3 years to:

- Establish a data management framework to anticipate and prevent risks related to the automation of Ariane 6 operations and production;

- Develop predictive maintenance and predictive quality algorithms that will be integrated into newly automated operations;

- Set up new logistic procedures intended to optimize the available resources as much as possible;

- Measure the benefits of its new practices in realistic operational scenarios;

- Support the transformation of skills, in particular by creating new worker profiles;

Publié le : 14 mai 2020